Vital to troubleshooting; Aqualia’s engineers have an enviable wealth of knowledge of indoor pool systems and the problems that regularly affect schemes. This comes with the territory for our chief engineer who entered the business as a technical manager for Calorex Heat Pumps, Europe’s most prolific supplier of indoor pool dehumidification schemes.

As a qualified and trained building services engineer before Calorex the subjects involved fall perfectly into his background in consultancy and with British Gas and Calorex.

The vast majority of indoor pool condensation and mould growth issues are not actually related to the environmental control scheme. The building design, thermal breaks and vapour control layers and materials of building construction are the normal culprits.

The Aqualia service is broad in respect of trouble shooting and can encompass.

Investigations into:

- Systems that cannot provide the required air or water conditions

- High running costs

- Poor air quality

- Noise complaints

- Controls systems malfunctions

- Boiler plant problems

- Building condensation / damage / mould growth

- Swimming pool condensation

- Adjacent area humidity/condensation/odours

- Understanding of systems and retrospective provision of instruction manuals

- Replacement of systems with the latest energy saving equipment.

With a full range of test equipment, Aqualia’s reports are backed up with factual test data to be used either to instigate repairs or to provide assistance to staff / owners in modifying the building to render it suitable.

But the equipment has to be used with a sound knowledge of the subject of psychrometrics, the study of air and water vapour mixtures, as well as the mechanical and electrical equipment that combine to provide the building protection and comfort conditioning to your indoor pool room.

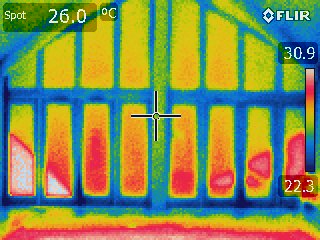

Aqualia’s equipment includes thermal imaging and smoke testing equipment to verify the building construction. Mechanical and electrical equipment includes a full range of temperature and humidity measuring devices as well as long term data logging for more difficult to assess issues.

Having spent so much time assessing and curing mistakes on problem pools makes us so much more aware of not repeating errors which in some cases were very subtle, such as thermally broken doors and windows fixed to the external skin of cavity walls.

Noise instrumentation, air flow measurement and fan speed tachometer together with ac and dc monitoring and data logging complete the comprehensive test facilities.

Moisture measurement and high definition endoscope are also available to test for water ingress, even into the furthest reaches of an underground ducting system and to investigate the effects of interstitial condensation, the moisture formation within walls where vapour control layers have been ineffective (or worse still completely absent).

The effects of a poor internal environment can quickly escalate to surface and internal structure damage. Thats why we are keen to use our experience of troubled buildings to make sure others mistakes are not repeated on your job.

Whilst this surveying and reporting is normally provided to owners and pool companies keen to get the system back on track, it is also provided as part of expert witness testimony in cases of legal dispute where out of court agreements can sadly not be reached

Troubleshooting equipment